Clamshell Blister Packaging

The popular clamshell blister packaging you see in retail stores is a product of thermoforming. Clamshells differ slightly from traditional blister packaging. We’ll walk you through how they’re different and in what situations they might be best.

What Is Custom Clamshell Blister Packaging?

Clamshells are a type of packaging used mostly in retail products that have hinges in the blister pack that allow them to pry open like a shell. Normally, a clamshell with one hinge will have a tab so it can be hung on a store peg. Clamshells with multiple hinges instead use a flat base which lets them be sat upright on shelving units. This type of packaging is excellent for showcasing retail products because customers can get a clear idea of the product through the blister pack. And, because they are thermoformed, clamshells can be customized to hold any product and take any shape.

How Does a Clamshell Differ From a Blister Package?

A blister pack is another type of packaging that uses a clear thermoformed layer to enclose a retail product, specifically in pharmaceutical, food, and small consumer good sales. The biggest difference between a clamshell and a blister pack is that a blister doesn’t have a hinge. Instead, it is usually attached to a card made of paperboard to hold the product stationary.

When Should a Manufacturer Use a Clamshell Package?

Clamshells should be used when a manufacturer needs to transport, contain, merchandise, or protect a retail item. A clamshell is made up of two sections with a hinge along the centerline that folds over and attaches to itself to form an enclosed container. They’re usually used for higher-priced items such as electronics, smart-phones, and even food.

Do Clamshells Have Size Limitations?

Clamshells have very little in the way of size restrictions. Size limits are mostly determined by tooling and machinery. If a consumer or industrial product is of a weight and size that can be hung from a display peg, it’s likely that it can be accommodated in clamshell packaging.

How Long Does Clamshell Packaging Take to Create?

Thermoforming times vary based on the type of machine making the clamshell, the size of the mold, and the thickness of the plastic. Most machines can make thousands to tens of thousands of clamshell packages on a single machine.

Flexible Packaging

Flexible packaging is one of the fastest-growing portions in today’s packaging industry. It combines the best qualities of paper, film, aluminum foil, paper, film, and plastic to provide a protective and reliable covering while using the least material possible. Flexible packaging is defined as any package or part of a package with a changeable shape, such as a liner, pouch, or bag. It’s used to distribute, market, and protect institutional and consumer products for industrial applications.

Custom flexible packaging is innovative and adds marketability and value to both food and retail products. It extends shelf life, ensuring food safety, and allows for resealability, ease of use, high printability, barrier protection, and even heating, with more advantages being discovered all the time.

The life cycle of custom flexible packaging pouches displays numerous sustainable advantages. First, pouches, bags, and foil create less waste, meaning less material in the landfill. Manufacturers also use fewer natural resources to create this packaging thanks to technological and innovative advances, and the production process now uses less energy and water consumption, volatile organic compounds, and greenhouse gas emissions. Plus, because the packaging is lighter-weight, it takes less fossil fuel and energy to transport products, leading to less environmental pollution. With its sustainability, resource conservation, customizability, and versatility, it’s a great time to consider upgrading an existing package line or creating a new product line with custom flexible packaging.

Flexible packaging has many more benefits as well:

- Again, decreased waste production

- Fewer emissions and greenhouse gases

- Less energy use in manufacturing and transportation

- Extends product shelf-life, especially for food

- Lightweight and easy to reseal, store, carry, and open

- Efficient product-to-package ratios

- Increased visibility of products

- Greater shelf appeal

- Ease of storage and transportation

- Improved dispensing and reclosure options

- Consumer convenience

- Indicates and maintains freshness

- Useful for a wide range of product categories

- Innovation

- Less consumer waste in landfills

Flexible packaging is at the head of the pack for important packaging trends in sustainability, consumer convenience, packaging performance and design, and production protection which creates positive impacts on businesses, consumers, and the environment. Fifty years ago, cellophane was the only clear film used to package products. Since then, technology and innovation have led to a revolution of lighter-weight packaging on printable substrates that enhances sealability, product protection, strength, and shelf appeal.

Every one of the hundreds of innovation examples in flexible packaging has started from a simple idea, such as making medication safer, lowering shipping costs, or keeping meat fresh. Custom flexible packaging pouches have made thousands of products safer, more enjoyable, and more convenient for consumers thanks to the commitment to sustainability, technology, and innovation in the industry.

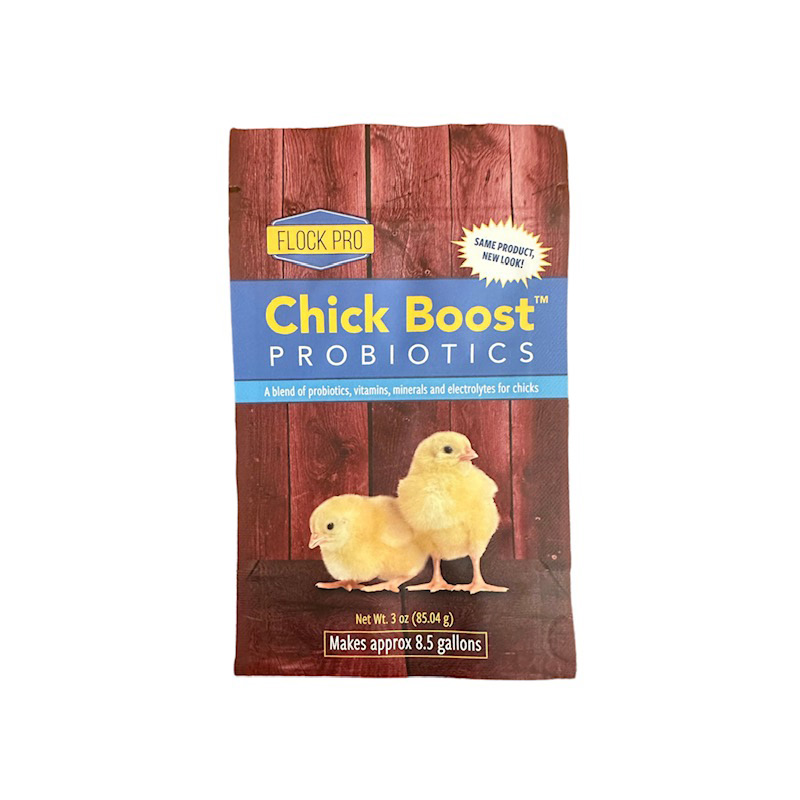

Foil packaging is essentially custom printed foil bags and Printed Roll stock. This flexible packaging is made by laminating several layers of various materials together. Typical standup pouches use several polymer layers placed on top of one another to create a structure that doesn’t chemically react to food or non-food products and forms a barrier against oxygen. Foil pouches go a step further with FDA (Food and Drug Administration) approved materials that produce toxicity- and contaminant-free films, making them safe for packaging food and non-food items. Looking for more reasons to switch to pouch packaging? Here are several advantages.

Unique Capabilities and Popular Sealed Packaging Format

Foil stand up pouches, Mylar foil pouches, and foil-lined kraft bags each have their own unique uses. Our customers can choose from stock orders or create custom printed packaging options and flexible packaging can be used for emergency preparedness items, food, sensitive electronics, and medical devices.

Foil Packaging Meets Secure and Sterile Packaging Needs

Whether you’re looking for food grade bags for food packaging or sterile high-barrier packaging for pharmaceutical branding, foil pouches and bags can offer convenience and make you stand out from your competitors. You’ll also find functional features such as tamper-evident seals and child-resistant zippers in today’s flexible packaging.

Stand Up Pouches Offer Material Reduction and Brand Recognition

As a brand, you’re looking out for your bottom line and the material reduction for a foil stand up pouch offers both economic and environmental benefits. It also appeals to customers looking for an on-the-go experience. Subscription service brands with a green initiative will be especially pleased with flexible packaging and benefit from lower shipping costs from lighter-weight packaging.

Foil stand up pouches are a great solution for food and pet food packaging, offering a proper seal from oxygen and moisture to keep food fresh while being a good alternative to aluminum trays and cans. Foil bags can be pasteurized and sterilized for food and non-food applications and are customizable in special features, design, and shape. Because they’re flexible, you’ll also have a range of presentation possibilities to choose from.

Flexible packaging options have become more and more popular with consumers and brand owners for their advantages over rigid packaging. They provide excellent product protection from contaminates, oxygen, moisture, and light while offering materials savings, source reduction, shipping savings, and space savings.

To get more information on how flexible packaging and clamshell packaging solutions can work for your product, contact Infinity Packaging Solutions today, serving greater San Diego County, Los Angeles County, and nationwide. Our flexible and blister packaging suppliers offer food, non-food, or medical grade item in flexible packaging, as well as packaging for retail products. Call us at 760-402-3364 or fill out our online form to get a free consultation and quote. Let us show you how our quality packaging can attract customers for your product and improve your branding.